Computer vision is rapidly emerging as one of the most impactful technologies in modern manufacturing. By enabling machines to interpret and act on visual data, computer vision opens up new opportunities to improve quality, efficiency, flexibility, and safety across the factory floor. As manufacturers accelerate their Industry 4.0 initiatives, computer vision is shifting from a niche automation tool to a strategic capability with enterprise-wide implications.

Driving the next generation of quality control

One of the greatest opportunities for computer vision lies in transforming quality inspection. Traditional manual inspection is slow, costly, and inconsistent, while rule-based machine vision struggles with complex or variable products. Modern computer vision systems, powered by deep learning, can detect subtle defects, cosmetic flaws, and assembly errors that were previously difficult or impossible to automate.

This capability allows manufacturers to move from sample-based inspection to 100% inline inspection, significantly reducing the risk of defective products reaching customers. Over time, the visual data collected also enables trend analysis, helping teams identify recurring defects and address root causes earlier in the production process.

Enabling flexible and intelligent automation

Manufacturing is increasingly characterized by high product variety and shorter product life cycles. Computer vision enables a new level of flexibility in automation by allowing robots and machines to adapt to variability rather than requiring perfectly controlled inputs.

Vision-guided robots can identify, locate, and orient parts in real time, making applications such as bin picking, adaptive assembly, and mixed-model production feasible at scale. This reduces reliance on custom tooling and rigid fixtures, lowering changeover costs and making automation viable for small- and medium-sized manufacturers.

Unlocking process transparency and optimization

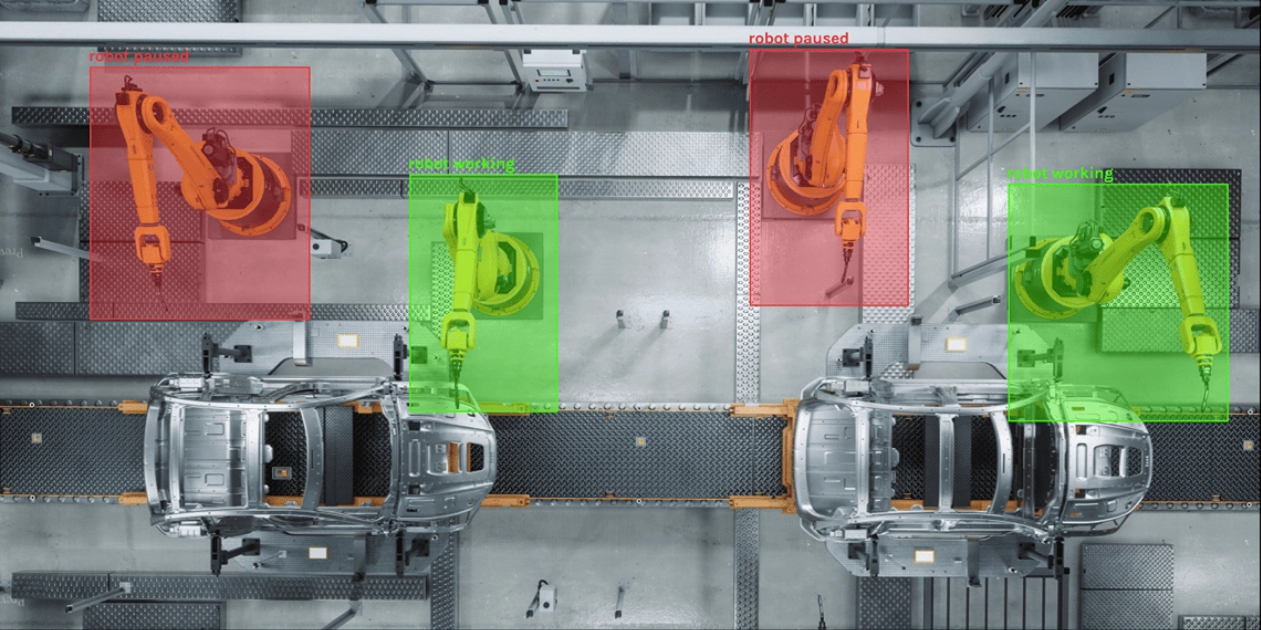

Another major opportunity lies in process monitoring and optimization. Computer vision systems can continuously observe manufacturing processes—such as welding, coating, filling, or packaging—and detect deviations as they occur. This real-time visibility allows manufacturers to intervene before defects propagate downstream.

When combined with analytics and manufacturing execution systems, vision data becomes a powerful source of operational intelligence. Manufacturers can uncover hidden inefficiencies, correlate visual indicators with process parameters, and continuously optimize throughput, yield, and energy usage.

Supporting predictive maintenance and reliability

Computer vision also creates new opportunities in predictive maintenance. By visually monitoring equipment, tools, and components, systems can detect early signs of wear, misalignment, leaks, or contamination. These visual cues often appear before traditional sensor data indicates a problem.

Integrating vision-based insights into maintenance strategies enables a shift from reactive or schedule-based maintenance to condition-based maintenance. This reduces unplanned downtime, extends asset life, and improves overall equipment effectiveness (OEE).

Enhancing worker safety and compliance

Safety and compliance represent another high-impact opportunity. Computer vision systems can monitor workspaces to identify unsafe behaviors, ensure the use of personal protective equipment (PPE), and detect proximity risks between humans and machines.

Unlike manual supervision, vision-based safety systems operate continuously and consistently, providing real-time alerts without disrupting operations. As regulations become stricter and labor shortages increase, these systems help manufacturers maintain safe environments while supporting productivity.

Scaling knowledge through data and AI

Beyond individual use cases, computer vision enables manufacturers to capture and scale operational knowledge. Visual data preserves expert insight that might otherwise be lost due to workforce turnover. AI models trained in one facility can often be adapted and deployed across multiple plants, creating standardized best practices.

As datasets grow, computer vision models become more accurate and more valuable, creating a compounding return on investment. This positions vision not just as an automation tool, but as a long-term data asset.

Looking ahead

The opportunities for computer vision in manufacturing are expanding as computing power moves to the edge, cameras become more affordable, and AI models grow more robust. Future systems will increasingly combine 2D and 3D vision, integrate with other AI modalities, and provide explainable insights rather than simple pass/fail decisions.

For manufacturers willing to invest in data, integration, and change management, computer vision offers a clear path toward smarter factories, more resilient operations, and sustained competitive advantage.